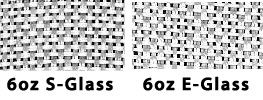

“S” Fiberglass Cloth (also known as S-Cloth or S-Glass) is sometimes used on the deck of surfboards for more impact resistance against heel dents and caving in the deck. In very basic terms, it has a tighter weave with more fibers per square inch. It is often used on “team” boards that have single layer glass schedules to keep the board super light, and then S-Glass is used for the single deck layer to keep the board usable longer.

S-glass feels exactly the same to the touch as E glass but it is about 30% stronger. S-glass is a more expensive material so surfboards made with s-glass will have a higher price tag as a result.

Stretch uses S-glass on all of his EPS Tech boards because he has found the added cost of the S-glass is well worth the extra durability and longevity of the board.

We can add S-Glass on the deck of any custom order board from Lost, Roberts, Rawson, etc as long as we know at the time of order.

Going deeper:

– “E” Glass (the most common type of surfboard fiberglass) was named because it was originally designed for electrical applications.

– S-glass is actually called S-2 fiberglass.

– It’s very unusual to use S-glass on the bottom of the board since it’s main purpose is to prevent heel dents and compressions. Usually shapers will only use s-glass on the deck and/or rails unless of course you are going to be riding your board upside down.